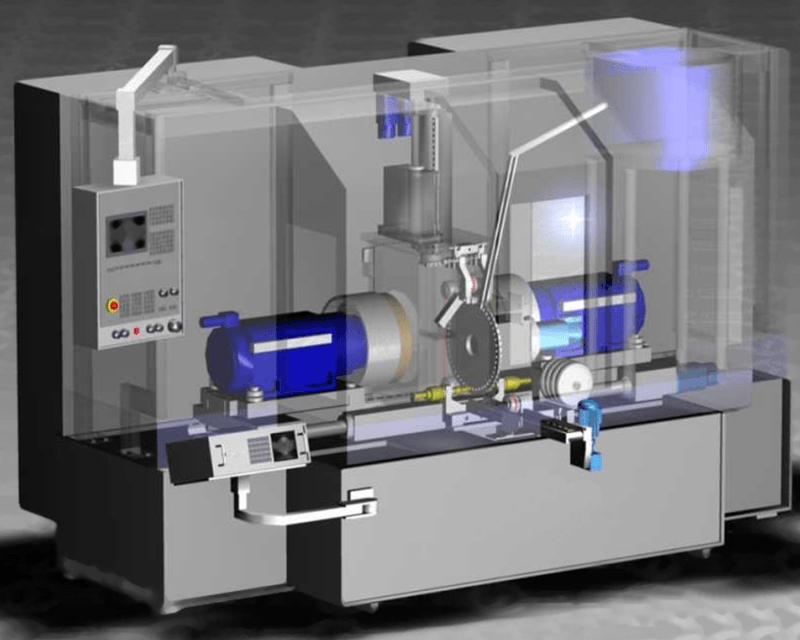

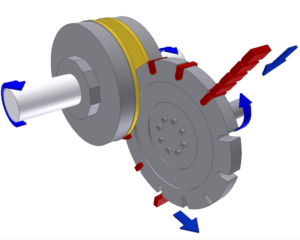

Double face grinding is the process of producing components with the highest requirements for the precision of the faces, with the smallest tolerances for flatness and squareness. The parts ground here are therefore frequently used for pump components (pendulums, rollers, blades). Economic processing of high quantities is possible thanks to fully automatic parts feeding and parts removal, including measuring control.

Product examples

Data

- Processing of workpieces from round material and profiles in part lengths from 5 to over 80mm length

- Length and angle tolerances within less than 0.01mm possible

- Grinding with CBN and corundum

- Online measurement with process control of the machine